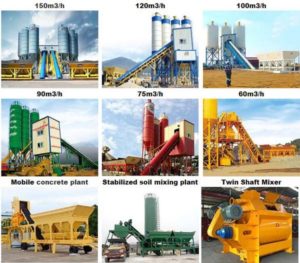

The model classification/output and composition of concete plant:

HZS25 type concrete batch mix plant , HZS35 type concrete batch mix plant, HZS50 type concrete batch mix plant and HZS75 type concrete batch mix plant belong to small concete plant. Small concete plant adopts wire rope lifting hopper to feed, occupies small area, and moves the machine conveniently and quickly, which is usually used in engineering projects.

HZS25 concete plant: When the theoretical discharge volume is 25 m3/per hour, the main machine adopts JS500 double horizontal axle forced concrete mixer, and the gradation and measurement system of the mixer are selected according to the formula.

HZS35 central mix concrete plant: JS750 concrete mixer can be used with bulk cement bin, screw conveyor, metering system and control system when theoretical discharging volume is 35m/h

HZS50 central mix concrete plant: when the theoretical discharge is 50m3/h, the main machine is JS1000 forced concrete mixer. According to the gradation of sand and stone, two, three or four silos of PLD1600 concrete mixing machine are selected. A simple concrete plant is composed of bulk cement silo, screw conveyor, cement metering system, water metering system and centralized control system, which is used in the project.

HZS60 concrete plant, HZS90 concrete plant and HZS120 concrete plant belong to medium-sized concrete batching plant. All concrete mixing stations above medium-sized are equipped with belt material, which covers a large area and has a large investment. Users need about 20 mu of land.

HZS60 concrete mixing plant: When the theoretical discharge is 60 m3 per hour, the main engine can adopt our own or Sigoma JS1000 concrete mixer. The concrete mixer usually uses the full pneumatic PLD1600 mixer, which is a small-sized medium-sized concrete batching plant. If the user wants to invest less, he can choose this type of batching plant equipment.

HZS75 concrete batch plant: When the theoretical discharging volume is 75 m3/h,the JS1500 concrete mixer produced by our factory can produce all commercial mixtures or semi-dry materials marked below C50. The overall performance of the equipment is close to that of medium-sized concrete batching plant.

HZS90 skip hoist type concrete batching plant: When the theoretical discharge is 90 m3 per hour, the main engine uses JS1500 double horizontal shaft concrete mixer produced by our factory , and equipped with PLD2400 mixer, belt conveyor, automatic centralized control system, etc. It is the choice of commercial mixing station and engineering concrete batching plant.

HZS120 skip hoist type concrete batching plant: The theoretical discharge is 120 m per hour, using the two-way mixer made by Stagma or Mix. The whole mixing station covers an area of about 65m*30m. The medium-sized mixing station with 120 m per hour discharge has a high return on investment.

HZS180 skip hoist type concrete batching plant, HZS240 skip hoist type concrete batching plant and HZS270 skip hoist type concrete batching plant are all large-scale concrete baching plant. Large-scale concrete baching plant has a high investment quota and covers a wide area. It needs about 50 mu of land. Users who invest in such large-scale concrete baching plant generally need to have strong economic strength.

HZS180 skip hoist type concrete batching plant: When the theoretical discharge is 180 m3 per hour, Sigoma JS3000 concrete mixer can be used, and two-side or top-floor concrete mixing station can be used.