How ready mix concrete plant to produce concrete?

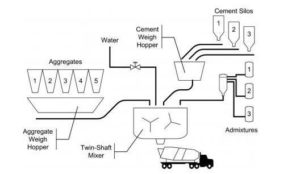

First of all ,let us see the below picture together,where all the actions for batching and mixing are shown. When production starts, system operator has to choose the desired recipe and insert the wanted quantity of concrete through the SCADA graphic user interface. Then, the batching process starts for the three different kinds of materials (there is no need for batching water), and process continues to the next step, which is the mixing process, only when all ingredients are batched properly. Mixing process starts simultaneously with the material induction in the mixer. Induction hierarchy, as noted above, depends on the specific recipe chosen. Mixing timer starts counting mixing time after all ingredients are placed into the mixer and when time elapses, mixing process stops and truck is loaded with concrete. When truck loading ends and mixer is empty, the production is completed and the system is ready for a new one.

Concrete is a mixture of cement, sand (fine aggregate), small stone or gravel (coarse aggregate) and admixtures. When water is mixed in with this product, it activates the cement, which is the element responsible for binding the mix together to form one solid mass. Cement is crushed limestone blended with other raw materials, such as shale and sand, ground into a powder and then heated in a rotary kiln. This process produces a cement clinker which is mixed with gypsum and ground further to produce cement.

On the one hand,we all know that a concrete batch plant is an important element in any concrete construction process, whether it is working as a central mixing plant on site or is offsite supplying ready mixed concrete to a project. The Concrete Batch Plant is depicted in Fig. 1. Batching is the process of weighing and introducing into the mixer the ingredients for a batch of concrete. All raw materials, cement, aggregates, water and admixtures are weighted and batched, at the aggregate and cement weigh hoppers and at the admixtures reactor respectively. Our concrete batch plant has five different types of aggregates each one stored in separate feeder bin. Cement composition types are three, placed in silos. Weigh hoppers have only one weigh meter and hence each type of aggregates or cement is added consequently and not all together. Admixtures, which are in liquid form, have also three different types tanked separately. Water is controlled using a meter system measuring the volume required. For the mixing process a twin shaft mixer is used to ensure that concrete is mixed thoroughly until it is uniform in appearance and all ingredients are evenly distributed. Finally, the freshly mixed concrete is deposited into trucks for delivery to the site of work.

The most crucial factor concerning concrete type and its mechanical and chemical properties is the materials proportion. Furthermore, other essential parameters such as material hierarchy – regarding the input sequence in the mixer – and the mixing time need to be considered in order to ensure the quality objective. All parameters regulated or not, are specified in the corresponding recipe specification sheet used for each concrete mix.

In example a medium strength mix, known as C20 mix, means that it will attain a strength equivalent to withstanding compression of 20 Nt/mm2 after 28 days. The proportions of materials for this mix are 1× cement, 2× fine aggregate and 4× coarse aggregate. The ideal water to cement ratio is 0.55 but, since most of the times aggregates are damp or even wringing wet, water mass must be calculated carefully to ensure that mix does not become too sloppy. In addition, the volume of water and the admixtures used can dictate the strength and the workability of the finished mix, and hence the proportioning task is very important. The mixing method and the mixer condition used to process the concrete are of high importance since they, in some measure, determine concrete’s microstructure and hence its overall performance.